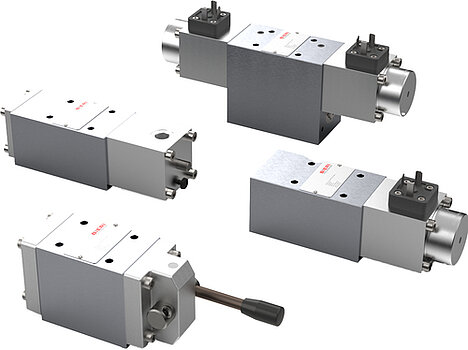

Directional poppet valves WV700

Directional seat valves of the WV700 series are directly controlled, seat-tight valves, suitable for switching by means of solenoid, air or manual actuation.

- Max. operating pressure: 700 bar

- Max. flow rate: 25 l/min

- Size: Size 6 to DIN 24340 / ISO 4401 / CETOP RP 121 H

Features

Direct operated, seat-tight, zinc-nickel coated solenoid and body made of corrosion-resistant heat-treated steel, as "standalone" valve or in valve linkage with sub-bases (AP700 and RP700)

Benefits

Seat-tight path functions with standardised NG6 connection surface to DIN 24340 / ISO 4401 / CETOP RP 121 H, solenoid can be rotated by 90° and no opening of the pressure-tight chamber required when changing the solenoid, good suitability for mineral oil

Industries & Applications

Control of cylinders in the higher pressure range as a fully-fledged replacement for spool valve technology (especially for seat-tight holding and clamping), machine tools, lifting technology, test benches or rescue equipment, power unit construction, bridge construction

Mounting

Pressure-balanced and hardened conical closing elements, with manual override, as 2/2-, 3/2-, 4/2-, 3/3- or 4/3-way globe valve with solenoid, manual or pneumatic actuation, mounting on individual sub-bases as "standalone" valve or in valve linkage with sub-bases (see technical data sheets AP700 and RP700), use of non-return valves and orifice plates possible by means of intermediate plate (see technical data sheets ZP700, RV700 and BL700), with guided closing element