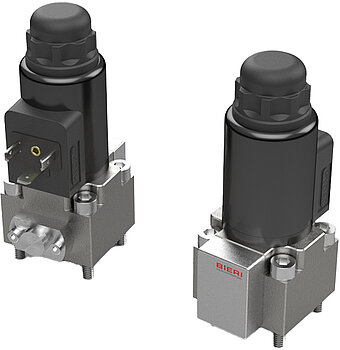

Directional poppet valves WVH-4B-Bi

Directional seat valves of the WVH-4B-Bi series are directly controlled, seat-tight and bidirectional valves, suitable for use with mineral oil but also with highly viscous media such as grease up to NLGI class 2.

- Max. operating pressure: 700 bar

- Max. flow rate: 12 l/min

- Nominal size: Size 4 to Bieri standard

Features

Direct operated, seat-tight, bidirectional, 360° rotatable and replaceable plug-in coil, zinc-nickel coated coil and body made of corrosion-resistant heat-treated steel, as "standalone" valve or in valve linkage with sub-bases (EAP-4B and APH/X-4B)

Benefits

Seat-tight bidirectional travel functions with defined connection surface, any orientation of the magnetic connector and no need to open the pressure-tight chamber when changing coils, high corrosion resistance, optimised dead space, good suitability for mineral oil but also for highly viscous media (grease), also suitable for very harsh ambient conditions and low temperatures

Industries & Applications

Control of cylinders in the higher pressure range as a fully-fledged replacement for spool valve technology (especially for seat-tight holding and clamping), machine tools, lifting technology, test benches or rescue equipment, unit construction, for highly viscous fluids / greases, use in lubrication systems

Mounting

Pressure-balanced and hardened conical closing elements, with manual override, as 2/2 or 3/2 valve with solenoid actuation, 360° rotatable and replaceable solenoid coil, mounting on individual sub-bases as "standalone" valve or in valve linkage with sub-bases (see technical data sheets EAP-4B and APH-4B), with guided closing element