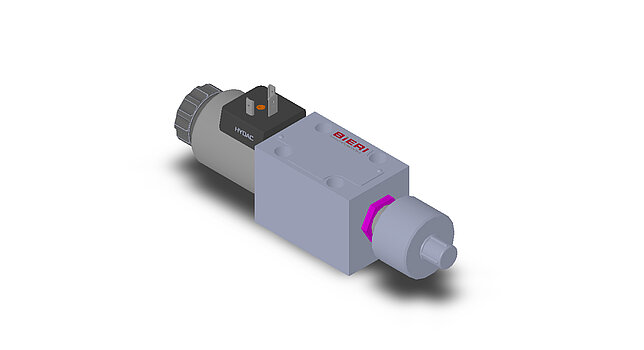

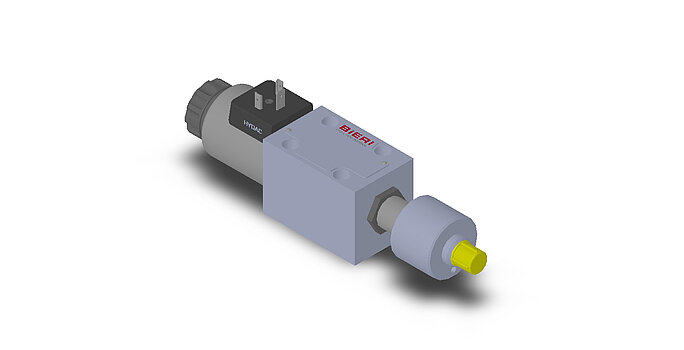

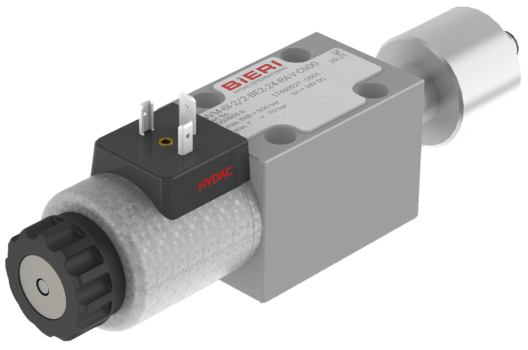

Directional poppet valves WVM-6I-R, position-monitored

Directional seat valves of the WVM-6I-R series are directly controlled, seat-tight and position-monitored valves, suitable for monitoring one or both valve positions.

- Max. operating pressure: 500 bar

- Max. flow rate: 12 l/min

- Nominal size: Size 6 to DIN 24340 / ISO 4401 / CETOP RP 121 H

Features

Direct operated, seat-tight, 360° rotatable and replaceable plug-in coil, zinc-nickel coated coil and body made of corrosion-resistant heat-treated steel, as "standalone" valve or in valve linkage with sub-bases (AP700 and RP700), position-monitored with dirt-resistant monitoring concept

Benefits

Seat-tight directional functions with standardised NG6 connection surface to DIN 24340 / ISO 4401 / CETOP RP 121 H, any orientation of the solenoid plug and no need to open the pressure-tight chamber when changing the coil, high corrosion resistance, good suitability for mineral oil, positive switching overlap (3/2 valves)

Industries & Applications

Control of cylinders in the higher pressure range as a fully-fledged replacement for spool valve technology (especially for seat-tight holding and clamping), machine tools, clamping device technology & fixture construction, lifting technology, test benches or rescue equipment, forming technology - clamping & clamping, hydraulic controls in accordance with DIN EN ISO 13849

Mounting

Pressure-balanced and hardened conical closing elements, with manual override, as 2/2 or 3/2-way valve with solenoid actuation, 360° rotatable and replaceable solenoid coil, mounting on individual sub-bases as "standalone" valve or in valve linkage with sub-bases (see technical data sheets AP700 and RP700), patented functional principle, with monitoring of one or both valve positions, non-contact and low-hysteresis transistor switches, with guided closing element